|

|

LCD AND LED DISPLAY FOR DATA-FEEDBACK

All radio remote controls in the M550 range can be enhanced with the data-feedback optionals which visualises on the alphanumerical LCD display, or LED, of parameters and messages from sensors installed in the unit. (For example: loading cells, distance from the trolley to the tower, length of lifting cables, wind speed, etc...). |

|

|

PLUG FOR SERIAL CONNECTING Transmitting units of the ZEUS and THOR series can be equipped with serial connecting plug to the receiver. Direct cable connection excludes the need for radio transmission, therefore overcoming problems regarding signal disturbances or the use of the product in areas where radiofrequency is not permitted or if the batteries run out. |

|

|

DYNAMIC SPEED CONTROL (DSC) Situations that require a lifting machine to exercise precise precision manoeuvres at a reduced speed, are becoming more frequent. As from today with the new DSC (Dynamic Speed Control) function, varying the load or precision needs can be satisfied immediately with a simple click directly from the operator on to the radio remote control With DSC it is possible to instantly correct the levels of the reduced speed ("snail") to adjust the response of the unit to specific work requirements. The new DSC function completes the already enhanced packet of technical solutions that IMET comprises for the control of machines with comparative actions. |

|

|

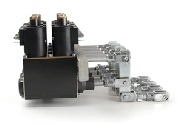

PWM ACTUATOR Is your crane equipped only with manual mechanical commands? IMET has the solution for you, in order to make your job easier, safer and more efficient: HYDRA-SYSTEM. A system of densely packed electro-hydraulic actuators that can be attached to radio remote controls, without the need for welding on the cross link, leaving the original hydraulic plant intact. : The main characteristics of IMET HYDRA-SYSTEM are the independence of its hydraulic circuit from the one on the crane, where it is installed thanks to a dedicated control panel. This choice stems from all malfunctioning that can be created by the mixing of oil from the hydraulic circuit from a crane that has been consumed by too much work. Another strong point is the optimal management of the control panel via an electric grid that integrates the "soft start" functioning and the "on demand" activation. |

|

|

INCREASE OF PISTON RUN KIT A kit that extends the course of the pistons up to +/-20mm is available to satisfy particular requirements |

|

|

DEDICATED FLANGING KIT It is possible to interface directly with the APT400 actuators with the manual proportional Walvoil SD6, SD8, Galtech and Parker distributors thanks to the dedicated flanging kit. This configuration leads to the removal of the re-start bar . |

|

|

THE TRANSPONDER The IMET transponder has been developed to overcome critical obstacles of radio transmitting from the operator and to the receiver onboard the machine. This can also result as being useful to resolve situations that require limits different from normal. In normal conditions the cover range is approx 100m but the presence of reinforced cement or metal walls and natural barriers can strongly interfere with radio transmission. Users of cleaning machines, cranes and forestry machines are typically subject to these problems. The compact size and the IP65 case with battery power, allow an easy and quick positioning of the transponder in the optimal spot. This can be matched with all IMET M550S systems by a simple synchronisation procedure. The original radio remote control can be used to work just as easy in the basic configuration only with the transmitter and receiver. SUPPLIED KIT: The supplied kit comprises: A M550TPDR transponder, a battery charger, two removable Ni-MH rechargeable batteries, a user manual and an EU declaration of conformity. |

|

|

MULTI RECEIVING AND/OR MULTI TRANSMITTING CONFIGURATION IMET provides its users with special configurations that allow, by merely using a selection command, alternative matching of a receiver plus a transmitter unit or from transmitters to one or more receiver. a) These are the available configurations to satisfy even the most complex operational needs in crane industry: Tandem, Acquire/Release, Master/Slave. b) Selectable receivers: allows selection from a single transmitter to up to 8 receivers or 8 combinations of more receivers. |

|

|

HAC RECEIVER UNIT WITH ATEX CERTIFICATION

Group II unit. Unit destined to be used in environments were the risk of an explosive atmosphere is high; High level of protection: category 2. Unit designed to be used in environments were the risk of an explosive atmosphere caused by gas, vapours, fogs or a mixture of air and dust, is high. Potentially explosive gas and dust protection system. The unit remains charged and operational in zones 1, 2 (G) and 21, 22 (D); Explosion-proof casing. ; Temperature class 85°C; Completely protected against dust and strong water jets (IP66); Predisposed drawer with a 1” IOS7/1RC press cable and ¾” IOS7/1RC barrier for live cables with these specifications: ATEX Ex ll2GD Exd llC IP 66; Range, obstacle free 70m. |

| IMET |

| ELCA |

| TELECRANE |

| JUUKO |

| TRISCO |